Welcome to Leader in Industrial Solution since 2005

Global Certificate: ISO 9001:2016

Welcome to Leader in Industrial Solution since 2005

Global Certificate: ISO 9001:2016

Stimex Engineers is a leading Manufacturers, Suppliers & Exporters of Shuttering Panel, Shuttering Accessories

Shuttering panels, also known as formwork panels, are temporary structures used in construction to create the mold for pouring concrete into specific shapes and sizes. These panels support the weight of the wet concrete until it sets and can bear its own load. They come in various materials such as timber, steel, or plastic, and they can be reusable or disposable depending on the project's requirements.

There are several types of shuttering panels used in construction:

Constructed from steel sheets or frames, steel formwork panels offer durability, stability, and reusability, making them suitable for high-rise buildings and large-scale projects.

Steel formworks are types of shuttering that are temporary construction elements used to hold concrete while it hardens. Steel is an ideal material for formwork because it will never bend or warp if designed appropriately while pouring concrete. Steel shuttering is capable of storing a big volume of concrete. Steel is brittle, making it unsuitable for bonding with concrete. Steel plates may be stacked to build higher constructions.

Steel formworks can interlock to each other and this can be used to keep the panels together for increased stability. The disadvantage of steel formworks is its weight: the plates might be difficult to move into place, which means heavy construction machinery may be required to properly place the panels.

Aluminum formwork panels are lightweight, durable, and offer high precision and smooth finishes. They are commonly used for residential and commercial projects.

Aluminium formworks are types of shuttering that is a construction system used to construct cast-in-place concrete structures. It is also a scheduling and control system for other construction works such as steel reinforcement, mechanical and electrical conduits and concrete placement.

The system is quick, easy to use, versatile, and cost effective. It is distinctive in that it precisely shapes all of the concrete in a construction, including walls, beams, columns, floor slabs, staircases, balconies, and different decorative features, in line with the design.

These panels are lightweight, easy to assemble, and can be used multiple times. They are often made from polypropylene or high-density polyethylene.

Plastic formworks are types of shuttering which are interlocking, light-weight structures that can be used more than 100 times. It may be utilized in standard concrete construction. This sort of shuttering is becoming increasingly popular for similar designs and major housing projects

When compared to alternative materials for concrete formworks, the use of plastic formworks for concrete construction offers various advantages such as durability, affordability, and flexibility. It is made of a special grade of plastic so that neither put materials cling to it nor chemical reactions occur between poured materials and the plastic shuttering, resulting in no patch on the surface of the reinforced concrete component. Water or freshly placed concrete leakages from different places of the formwork are avoided thanks to the formwork’s precise interlocking system. Furthermore, it is the most labor-friendly system since it is easy to setup it and it also has much less weight when compared to other forms of formwork systems.

These panels combine different materials, such as wood and plastic, to leverage the benefits of each material while minimizing their drawbacks. They offer a balance of strength, flexibility, and cost-effectiveness.

Fabric formworks, also known as flexible formwork, are types of shuttering that are made of fabric. This technique employs high-strength and lightweight fabric sheets that are meant to arrange to the fluidity of concrete and produce distinctive architectural shapes.

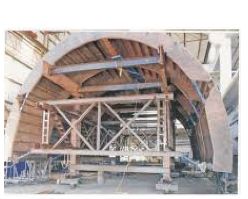

Tunnel formworks are types of shuttering that enables the contractor to cast walls and slabs in a single operation throughout the daily cycle. It is recognized as a modern form of construction because it combines the speed, quality, and precision of factory/off-site manufacturing with the flexibility and economics of in-situ construction. The great result is a cellular reinforced structure with sufficiently high-quality surfaces that require very minor finishing for direct decorating, while the end walls and facades are simply finished with thermally insulated components that may be clad as needed.

The system produces an efficient load-bearing structure that can be used in a wide range of applications. It is especially useful in projects requiring repeating cellular construction, such as residential towers, hotels, student dormitories, prisons and barracks.

Permanent insulated formwork is a building technology that employs lightweight formwork which is made of an insulation material to support concrete walls while they are being cast in-situ and is then kept in place as insulation.

Permanent insulated concrete formwork includes twin-walled expanded insulation panels that are well-stacked to form a permanent formwork that holds ready-mixed concrete for the walls. The permanent insulated formwork is left in situ to ensure that the final building’s walls are completely thermally insulated. It also creates a consistent surface that is suitable for most finishes and appropriate coating systems to be applied directly. Many insulated concrete formwork systems include a flooring system as well.

Stay in place formwork is meant to stay in place after the concrete has hardened, providing axial and shear supports. Prefabricated and fiber-reinforced plastic forms are used to construct this formwork on-site. It is mostly utilized in piers and columns, as well as providing corrosion resistance and resistance to various sorts of environmental damage.

Coffor, a type of stay in place formwork, is a structural stay-in-place formwork technique that is used to construct reinforced concrete walls. It is made up of two rib lath filtration grids that are strengthened by C profiles. Connectors made of articulated rebar link the grids together.

Concrete is poured into Coffor once Coffor is anchored to the ground. While the fluid concrete becomes semi-solid, the excess water drains through the grids. The pressure on the grids is reduced when the excess water is removed. Coffor remains inside the building and serves as a kind of reinforcement.